Products and Solutions

Excellent capabilities and rich experience in design and production, committed to provide professional solutions for intelligent manufacturing equipment and systems integration. Learn More >

About us

AUTOBOX is one of the industry's leading automation experts. With a sophisticated company culture, we are constantly striving for excellence. Learn More >

Career

At AUTOBOX, we all work together to achieve great things. Here, you'll do more than join something, you'll show your strengths in cooperation. Learn More >

為了您的良好體驗

請將手機豎屏操作

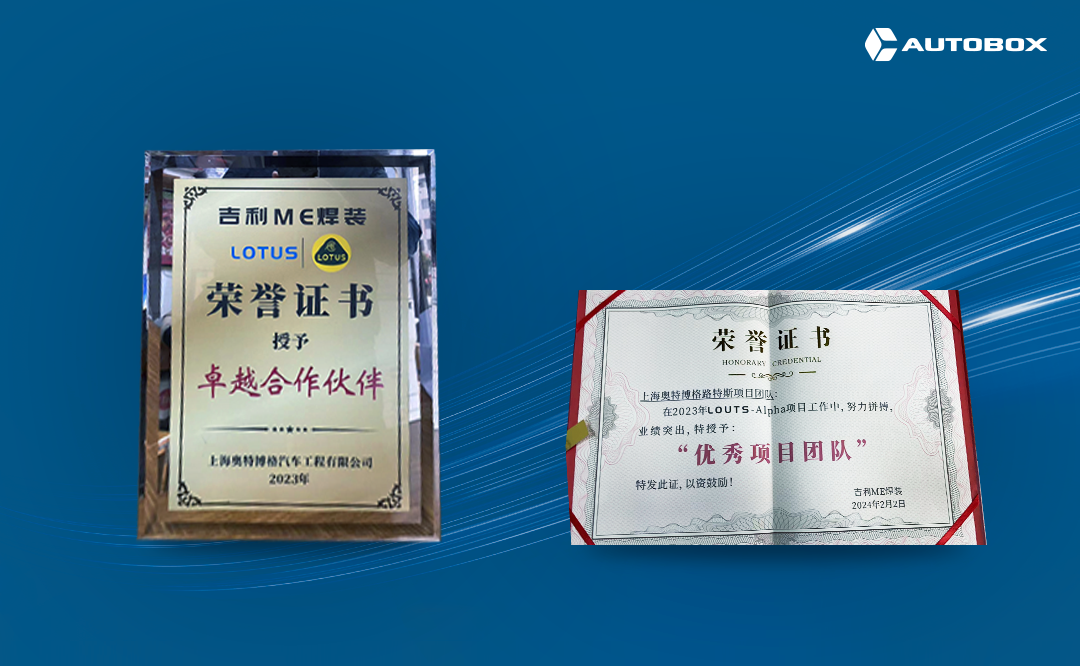

Honor | “Excellent Partner” Award and “Outstanding Project Team” Award from LOTUS

2024-02-22News Content

LOTUS, a super-luxury car brand of Geely Group, not only inherits the excellent tradition of British automobile manufacturing, but also takes the lead in embracing the future of electrification and intelligence with a pioneering attitude.

Recently, AUTOBOX has won the“Excellent Partner” Award and “Outstanding Project Team” Award from LOTUS with its excellent delivery quality, outstanding service quality and efficient teamwork. This honor is not only the recognition of AUTOBOX's excellent performance in the Lotus project, but also the affirmation of its insistence on high-quality services and continuous innovation for a long time.

Gather strength

In 2020, AUTOBOX successfully undertook the project of Lotus' first domestic super-luxury sports car ELETRE. This cooperation with milestone significance was highly valued and fully invested by both sides. AUTOBOX, with its professional strength in the field of intelligent manufacturing, provided a solid guarantee for the successful listing of this model. Based on such a deep cooperation foundation and mutual trust, it also won the subsequent cooperation opportunity of the Alpha model, further deepening the cooperation relationship between the two sides and jointly exploring a broader future.

Multicomponent process

The car manufacturing process of Lotus is exquisite, showing excellent performance and quality, which stems from the brand's persistent pursuit of technological innovation and the unique manufacturing concept of craftsmanship. The ELETRE and EMEYA projects have applied as many as 16 core connection process, including SRE, laser welding, aluminum spot welding, FDS, SPR, etc., and at the same time, advanced applications such as the automatic hemming of the side wall door opening and the automatic tightening and assembly of the rear tailgate have also been introduced. It is worth mentioning that this is the first global mass production realization of multiple processes. Among them, the door opening hemming and other process jointly developed by AUTOBOX and LOTUS have achieved the top-level body rigidity and the best lightweight effect in the same class.

Innovation-driven

In the welding workshop production line project of the LOTUS EMEYA, AUTOBOX project team undertook the construction and integration work of the entire production line. In this project, the slide table storage position system was adopted for all the lines. This innovative design not only greatly facilitated the rapid switching of multiple models in the later stage, but also significantly improved the flexibility of the lines. Although this increased the difficulty of commissioning, AUTOBOX project team, with its superb technology and unremitting efforts, successfully overcame the challenges and created an efficient, flexible and adaptable manufacturing system for the production line.

The obtaining of honors is not only the affirmation of the past efforts of AUTOBOX , but also the encouragement for our future development. As an important partner of LOTUS, we will continue to uphold the craftsmanship spirit, deeply cultivate in the technical field, and closely cooperate with customer. Through excellent products and high-quality services, we will help realize the brand mission of "We are first, last and always for the drivers", and inject continuous innovative value into the automotive industry.

News Picture